BBS supplies racing wheels to many leading teams in the motorsports world, including Formula One, and supplies high-quality forged wheels to European premium cars and other automakers. We visited the founder of BBS and talked about the roots of the company for half a century.

BBS’s belief is to use the know-how acquired in the race to serve customers

Haslach is a peaceful and scenic city in south-west Germany located near the Black Forest. Headquartered in this small and beautiful town, BBS Motorsports GmbH is the forefront base for BBS in Europe, supplying world top forged aluminum wheels to European customers and other top-tier racing teams. We visited their factory at the headquarters and interviewed Mr. Heinrich Baumgartner, founder and former CEO of BBS in Germany, about the turbulent half century since its foundation.

Mr. Heinrich Baumgartner, founder of BBS, obtained a patent in the casting technology field in 2014. At 83, he continues to pursue new technologies.

“During my childhood, which was during World War II, we were short on supplies and money. I could not go to school because of the chaos after the war, so I don’t have educational backgrounds,” said Baumgartner, now 83, who started talking calmly about his background.

“In 1960, I opened an automobile maintenance and repair shop in the town of Schiltach, Germany. From around the next year I got into car racing and in customizing Hans Grasse, which was a modern and sporty car back then. However, the company wasn’t in a good condition, as I invested the money I earned with my business into racing activities,” he said with nostalgia.

He said he went through daily trial and error to enhance the potential of the car, pursuing speed and running stability based on his racing experience. Thanks to such efforts, Baumgartner swept the podiums with his Grasse. This also helped his car repair business, as friends and car lovers who heard of his victory started asking him to tune-up their own cars.

“At the time, there were almost no tuning parts available in the market, so small car shops like my factory worked out their own ideas and made tuning products by hand. It was around that time that the famous tuner AMG was established.”

Various parts and accessories are widely available nowadays. However, in the 1970s German car market, where the ownership rate of private cars just began to rise amid rapid economic growth, tuning parts were mostly made by individual engineers with their original techniques, and their sales mostly relied on word-of-mouth reputation.

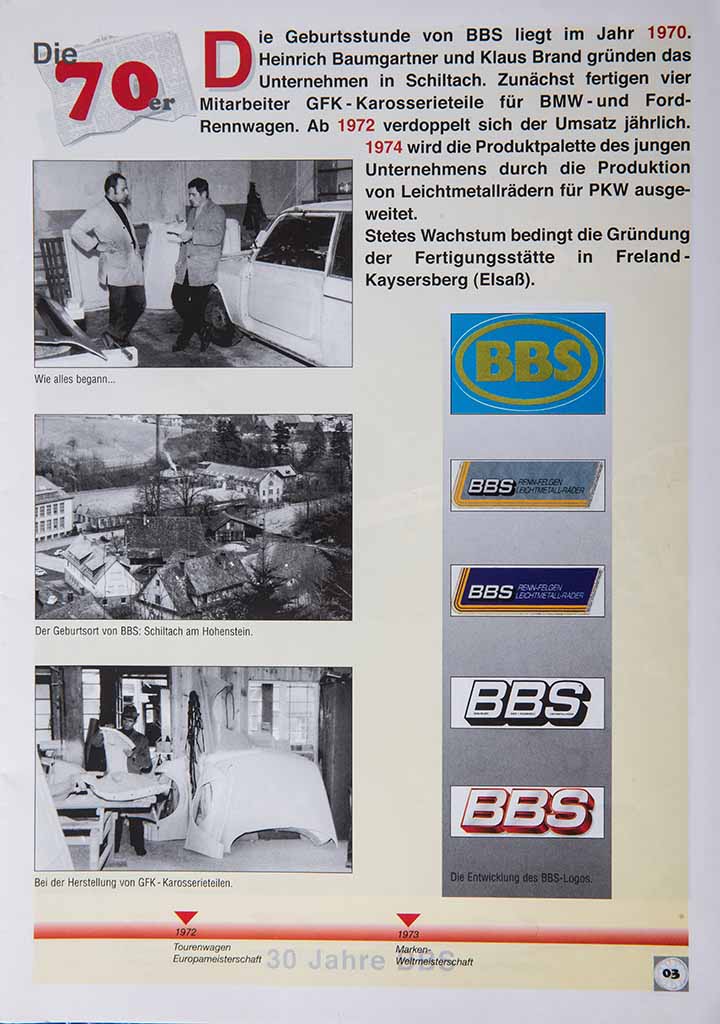

Since its establishment in 1970, BBS has consistently been close to motorsports. Its style has not changed even after half a century.

After Grasse was acquired by BMW, Baumgartner switched his base cars to BMW. He also began racing car construction. As a constructor, he started marketing activities through his communication with the racing teams, hearing their demands and problems.

“Looking back as a racing driver, I wasn’t always at the top level, but I wanted to use my knowledge gained in racing to serve my customers. I did something like a delivery person taking small requests from customers.” He laughs, remembering his days in the circuit in the 70s.

According to documents at the time of BBS’s founding, automotive engineers, Baumgartner and Brandt set up auto parts company in the town of Schiltach. The company took the initials of each and named BBS.

As he continued to talk to racing teams, he realized that the wheel was the key to reducing the weight of the car, which was a challenge many teams were facing.

“At that time, we were trying to reduce weight by using FRP (glass fiber reinforced plastic) for the body; a material that was rarely used at that time. One day the wheels suddenly caught my eyes. We developed wheels suitable for race cars through repeated trial and error, such as expanding the rim width or adding a welding process.”

Although two- and three-piece wheels already existed at that time, steel wheels were still very common within category races. In the time when no one thought of making the wheels itself stronger and lighter, Baumgartner was one of the first people to focus on light aluminum alloy, which has a high strength-to-weight ratio. This was the origin of the BBS wheel.

This unique concept of aluminum wheels came from the thoughts and ideas of his old friends and acquaintances who were skilled craftsmen. It was the wisdom, curiosity and passion of the people of the “Black Forest” region that made the first BBS Aluminum wheel. “It was pure passion.” Baumgartner recalls.

Both factory-backed teams and amateur teams are important customers

It is well known that the BBS’s three-piece aluminum wheels have helped many teams win numerous crowns. Years later, the introduction of Japanese aluminum forging technology significantly improved the sophistication and quality of the design, as well as the lightness and strength of the wheel. As motorsports became popular in Europe in the 1980s, automobile aftermarket parts were booming with young people dressing up their cars with BBS aluminum wheels.

BBS was renowned in the motorsport industry for its innovative ideas and outstanding development skills, supplying racing wheels to top European factory-backed teams such as F1 Scuderia Ferrari and BMW Motorsport.

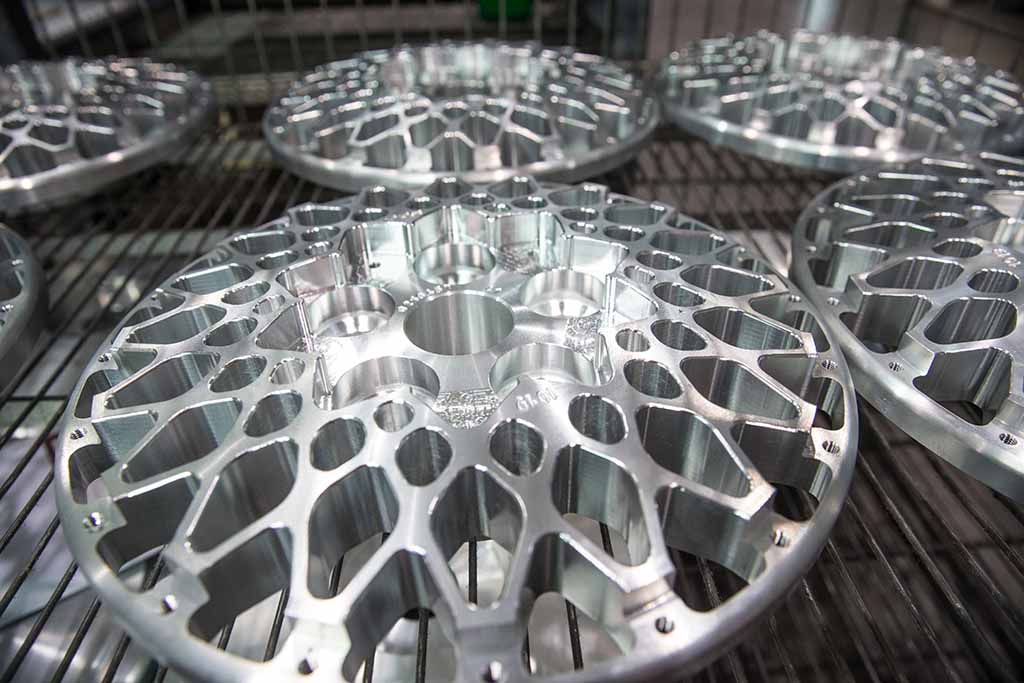

Meanwhile, the development of forged aluminum wheels by BBS has made a leap forward to products using cutting-edge materials such as lighter magnesium and high-strength extra-super duralumin. They have been globally supplied to motorsports teams for various races, such as the Le Mans, Formula One, 24 Hours Nürburgring and IMSA races in North America, and continue to demonstrate its performance to this day. Furthermore, the knowledge and advanced technology gained from their motorsports experience are being fed back to the development of their aftermarket wheels.

Surprisingly, Baumgartner says he has only visited the big races a few times, since he usually stayed at the manufacturing site working day and night with his employees to deliver stable and high-quality products to his customers.

Wheel manufacturing is now mainly mechanized, but still the process of finishing with the sharpened sense of skilled workers is existing. And it us common to both BBS factories in Japan and Germany.

“My products may have helped many teams win many races, but I’m not interested in the glory of the past. Whether it’s a factory-backed team or an amateur, they are all equally important customers to me.”

Baumgartner worked extremely hard playing multiple roles in his factory. He proudly stayed behind the scenes as a craftsman to serve his customers. Such craftsmanship was the fundamental factor that made BBS the top brand of forged aluminum wheels, now essential to the motorsports scene.

We asked Baumgartner about the cross spokes, which is one of the symbolic designs that stands out in a BBS wheel.

“This spoke design was logically created for technical reasons. We came up with a unique and high-quality design as a result of making the best use of our technologies,” he answered.

“We will respond to demands from racing teams to classic car owners as much as possible,” said Roman Müller, head of BBS Motorsport.

“The unique design of the BBS brand has been passed on as our spirit, although it has gradually changed as the time and technology evolved. As a top brand, it is very important to have a characteristic design that can be recognized at a glance, and this quality is the tradition BBS has built over the years. Many car manufacturers and aftermarket customers still demand our traditional cross-spoke design wheels.”

Roman Müller, present CEO of BBS Motorsports GmbH, continued. He was in charge of wheel development during the golden age of Formula One, and supported the victories of the top drivers such as Michael Schumacher.

The belief and passion for manufacturing, which has always been valued since its founding, is the reason why BBS wheels continue to be loved across times and borders.

BBS is taking on OEM production of genuine wheels for high-performance cars, but also supply high quality wheels to racing teams around the world. The cross spoke design wheel is iconic symbol of BBS.

Author:M.Ikenohara Photo:D.Reinhard/W.Tamura